Layanan Stamping Logam Kustom China

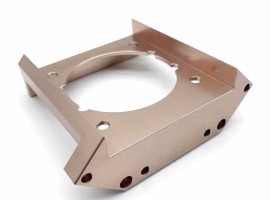

Ming Xiao Manufacturing Co, Ltd adalah spesialis dalam Bagian Stamping Logam layanan kustom lebih dari 15 tahun, kami kustom memproduksi semua jenis bagian stamping logam, seperti: kurung stamping logam, casing logam, bingkai logam, rumah logam, penjepit logam, klip logam, mesin cuci logam, pelat dasar logam, terminal kontak listrik, dll.

Apa itu stempel?

Stamping adalah proses pembentukan benda kerja (stamping part) dengan menerapkan gaya eksternal pada pelat, strip, pipa dan profil dengan menekan dan mati untuk menghasilkan deformasi atau pemisahan plastis. Stamping dan penempaan termasuk dalam pemrosesan pembentukan (atau pemesinan tekanan). Bahan stamping terutama pelat baja canai panas dan canai dingin dan strip baja.

Stamping adalah teknologi produksi bagian-bagian produk dengan bentuk, ukuran dan kinerja tertentu dengan menggunakan kekuatan peralatan stamping konvensional atau khusus untuk membuat lembaran logam langsung berubah bentuk dan berubah bentuk di dalam cetakan. Lembaran logam, cetakan dan peralatan adalah tiga elemen proses stamping.

Stamping Panas Dan Stamping Dingin

Menurut suhu stamping, dapat dibagi menjadi hot stamping dan cold stamping. Yang pertama cocok untuk pemrosesan lembaran logam dengan ketahanan deformasi tinggi dan plastisitas yang buruk, sedangkan yang kedua dilakukan pada suhu kamar, yang merupakan metode stamping umum untuk pelat tipis. Ini adalah salah satu metode utama pemrosesan logam-plastik (atau pemesinan bertekanan), dan juga termasuk dalam teknologi rekayasa pembentukan material.

Stamping Die Untuk Pembentukan Lembaran Logam

Die yang digunakan untuk stamping disebut stamping die, atau die. Punching die adalah alat khusus untuk memproses bahan batch (logam atau non-logam) ke dalam bagian stamping yang diperlukan. Punching die sangat penting dalam stamping. Tanpa meninju mati yang memenuhi persyaratan, stamping massal sulit dilakukan. Tanpa die lanjutan, proses stamping lanjutan tidak dapat direalisasikan. Proses stamping dan die, peralatan stamping dan bahan stamping merupakan tiga elemen dari proses stamping, hanya jika mereka menggabungkan satu sama lain untuk mendapatkan bagian stamping.

Langkah-Langkah Proses Stamping

Stamping terutama diklasifikasikan menurut teknologi, yang dapat dibagi menjadi dua kategori: proses pemisahan dan proses pembentukan.

Proses pemisahan, disebut juga blanking, bertujuan untuk memisahkan bagian stamping sepanjang garis kontur dan memastikan persyaratan kualitas bagian pemisahan.

Tujuan dari proses pembentukan adalah untuk membuat lembaran logam berubah bentuk menjadi plastis tanpa merusak blanko, dan membuat benda kerja dengan bentuk dan ukuran yang diinginkan. Dalam produksi sebenarnya, berbagai macam proses biasanya diterapkan pada suatu benda kerja. Mengosongkan, membengkokkan, menggeser, meregangkan, menggembung, memutar dan meluruskan adalah proses stamping utama.

Proses pemisahan

(kosong)

Ini adalah proses stamping dasar menggunakan bahan pemisahan mati. Itu bisa langsung dibuat menjadi bagian datar atau untuk proses stamping lainnya seperti membungkuk, menggambar, membentuk dan sebagainya. Itu juga dapat dipotong dan dipangkas pada bagian stamping yang terbentuk. Blanking banyak digunakan di otomotif, peralatan listrik rumah tangga, elektronik, instrumentasi, mesin, kereta api, komunikasi, industri kimia, industri ringan, tekstil dan kedirgantaraan dan sektor industri lainnya. Proses meninju menyumbang sekitar 50% hingga 60% dari keseluruhan proses stamping.

Proses pembentukan

Bending: metode pembentukan plastik untuk menekuk pelat logam, fitting dan profil ke dalam sudut, kelengkungan, dan bentuk tertentu. Bending adalah salah satu proses utama yang banyak digunakan dalam produksi bagian stamping. Pembengkokan material logam pada dasarnya merupakan proses deformasi elastik-plastis. Setelah dibongkar, benda kerja akan menghasilkan pemulihan elastis dan deformasi, yang disebut springback. Springback mempengaruhi akurasi benda kerja, yang merupakan teknologi utama yang harus diperhatikan dalam proses bending.

Gambaran mendalam Proses Stamping

Deep drawing, juga dikenal sebagai drawing atau calendering, adalah proses stamping dengan menggunakan cetakan untuk membuat blanko datar menjadi blanko setelah dilubangi. Proses deep drawing dapat digunakan untuk membuat bagian berdinding tipis berbentuk silinder, berundak, meruncing, bulat, berbentuk kotak, dan bentuk tidak beraturan lainnya. Jika digabungkan dengan proses stamping lainnya, komponen dengan bentuk yang sangat rumit juga dapat diproduksi.

Dalam produksi stamping, ada banyak macam bagian gambar. Karena ciri-ciri geometrinya yang berbeda, posisi zona deformasi, sifat deformasi, distribusi deformasi, dan keadaan tegangan serta distribusi setiap bagian blanko merupakan perbedaan yang cukup mendasar.

Oleh karena itu, penentuan parameter proses, nomor dan urutan prosedur, serta prinsip desain dan metode desain cetakan berbeda. Menurut karakteristik mekanika deformasi, semua jenis bagian gambar dalam dapat dibagi menjadi empat jenis: benda putar dinding lurus (bagian silinder), benda tidak berputar dinding lurus (badan kotak), badan slewing permukaan (bagian bentuk permukaan) dan permukaan benda yang tidak berputar.

Gaya tarik diterapkan pada bahan lembaran oleh cetakan gambar untuk menghasilkan tegangan tarik dan regangan tarik yang tidak merata, dan permukaan ikatan pelat dan cetakan gambar secara bertahap mengembang sampai benar-benar sesuai dengan model gambar. Objek utama gambar adalah kulit hiperbolik dengan plastik tertentu, luas permukaan besar, kelengkungan halus dan halus, dan kualitas tinggi (bentuk akurat, streamline halus, dan kualitas stabil). Karena peralatan dan peralatan proses relatif sederhana, biaya menggambarnya rendah dan fleksibel, tetapi pemanfaatan dan produktivitas materialnya rendah.

Proses yang Digunakan Untuk Deep Drwaing

Pemintalan adalah teknologi pemrosesan putar logam. Dalam proses pengolahannya, billet diputar secara aktif dengan die yang berputar atau kepala pemintal mengelilingi billet dan die yang berputar secara aktif, dan kepala yang berputar diumpankan oleh die inti dan blanko. Bagian kosong yang berputar diperoleh dengan deformasi parsial terus menerus dari benda kerja tersebut.

Membentuk adalah dua kali pemangkasan bentuk produk dengan menggunakan alat bentuk. Hal ini terutama tercermin pada bidang tekanan, peluru dan sebagainya. Mengingat elastisitas beberapa bahan, tidak mungkin menjamin kualitas cetakannya.

Menonjol adalah metode pengolahan untuk memperoleh suku cadang dengan menggunakan die untuk membuat lembaran logam menipis dan menambah luas permukaan. Biasanya digunakan dalam bentuk undulasi, penonjolan blanko berbentuk silinder (atau tubular), dan peregangan blanko datar. Penonjolan dapat dilakukan dengan berbagai metode, seperti penonjolan, penonjolan kaku, dan penonjolan hidrolik.

bergelang adalah suatu metode pengolahan plastik untuk membengkokkan material pada area strip sempit tepi blanko atau tepi blanko pada garis lengkung atau lurus. Flanging terutama digunakan untuk memperkuat tepi bagian, menghilangkan tepi tajam dan membuat bagian dirakit dan dihubungkan dengan bagian lain pada bagian atau bagian tiga dimensi dengan bentuk spesifik yang kompleks dan ruang yang wajar, dan meningkatkan kekakuan dari bagian tersebut. bagian. Dalam pembentukan lembaran logam besar, ini juga dapat digunakan sebagai sarana untuk mengendalikan kerusakan atau kekusutan. Sehingga banyak digunakan dalam mobil, penerbangan, dirgantara, elektronik dan peralatan rumah tangga.

Leher adalah metode stamping yang mengurangi diameter bagian berongga bergelang atau diameter ujung terbuka tabung kosong. Perubahan diameter ujung benda kerja sebelum dan sesudah necking tidak boleh terlalu besar, jika tidak material ujung akan kusut karena deformasi kompresi yang parah. Oleh karena itu, sering kali perlu dilakukan penyusutan leher dari diameter yang lebih kecil dengan diameter yang lebih besar.